- sales@racegears.com

- 720-545-2274

Crown Race Gears / Quality Control

Ring and Pinion Gear Quality Control

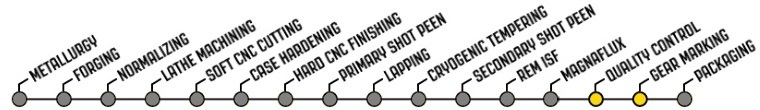

Creating the best ring and pinion gears on the market requires a long list of complex procedures performed in highly precise ways and in a specific order. Even the smallest oversight at any stage between the formation of the steel alloy to the final REM ISF finishing process can create or leave behind defects that could ultimately lead to gear failure during use. Due to the complexity of the entire process and the almost unobtainably high standards that we hold for the gears that bear our name, Crown Race Gears opperates one of the strictest quailty control programs in the industry.

Quality Control Program Highlights

- QC program developed and implemented by certified ISO 9001 Quality Management Systems Lead Auditor

- QC process managed on-site by certified ISO 9001 Quality Management Systems Lead Auditor

- Strict vetting of all approved vendors

- Continuous calibration of all equipment and tooling

- Detailed QC traveller form follows every gear from start to finish

- Visual inspections and verification measurements taken after every process

- Cutting tools replaced or sharpened at the first signs of wear

- Periodic Magnaflux inpsections (as per statistical analysis)

- Periodic surface hardness checks (as per statistical analysis)

- Periodic lab analysis of core microstructure, and surface finish

Ring and Pinion Gear Marking

Once a new set of Crown Race Gears passes their final quality inspection, they are ready to be marked with their identifying details and unique serial number. This is done using a permanent, chemical etching process that cannot be tampered with and allows us to keep a record of each gear set for warranty and quality control purposes.

*Race team names or other special characters can be added to these markings by special request at the discression of Crown Race Gears.